Refurbishing Old Slate Tiles with Coarse Milling Pads in the Lake District

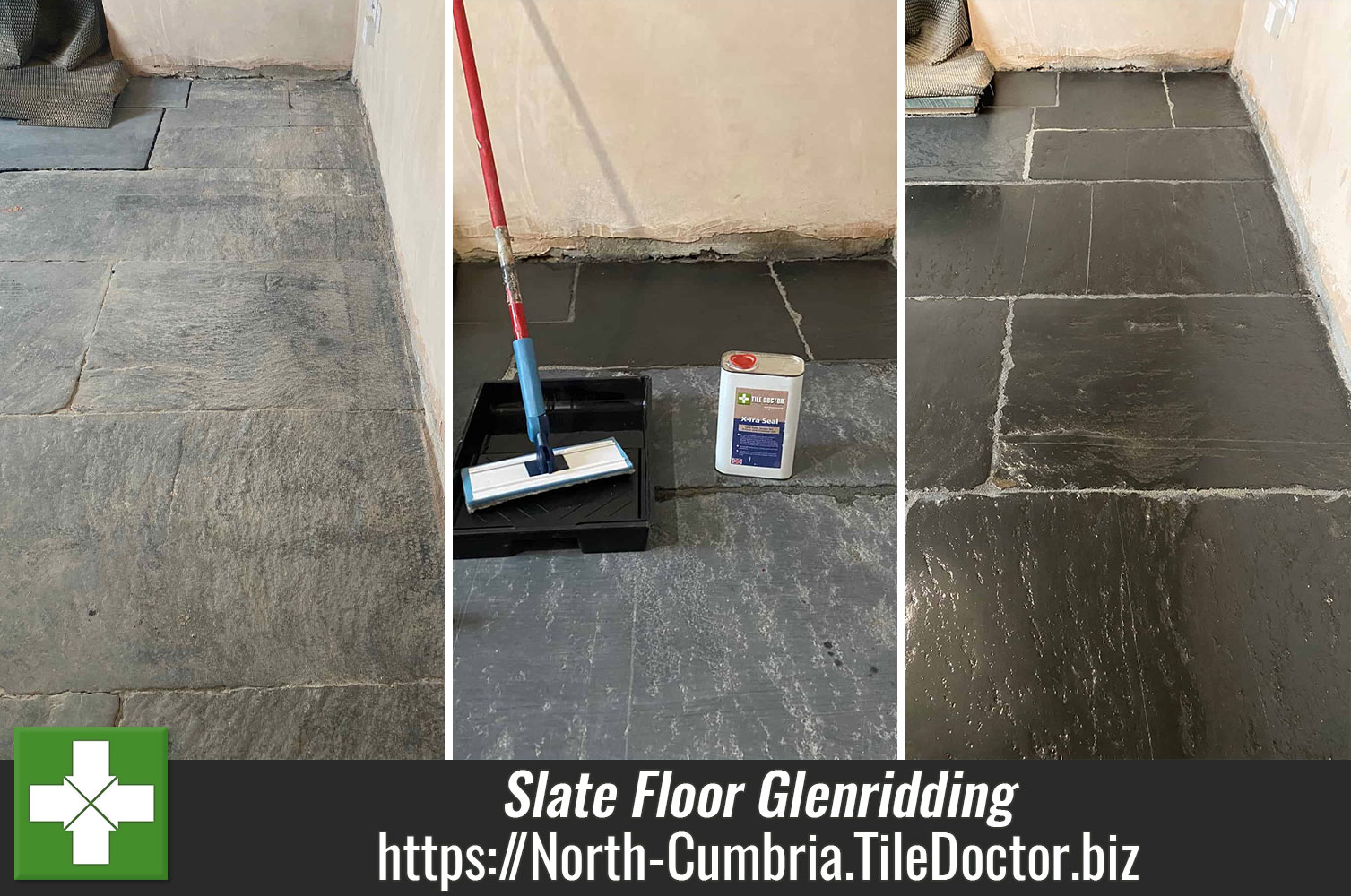

I thought I would share the details of this Black Slate floor renovation we recently completed in Glenridding in Ullswater. Slate is a popular choice for flooring in the Lake District due to its abundance in the area so I’m sure it will be relief to some to know that it can be restored regardless of the state it gets into.

|  |

This House was actually an old Miners Cottage based in the Valley of Glenridding and the Black Slate was actually from the mine itself. After nearly two hundred years of use the old floor was still in good structural condition although the pointing had perished in many areas and needed replacing

Unless it’s being completely removed, I always recommend putting old floors like this back into use. Reason being the lack of a damp proof membrane which if in place would prevent moisture rising through the floor; old floors like these don’t have a DPM so its best to maintain them and let them breathe so moisture can evaporate at the surface. Cover them up and you risk damp building up under the floor where it can reach out to the walls.

Re-Pointing Black Slate Flagstones in the Lake District

The first step of the renovation was to knock out the remaining pointing with an 8lb Titan hammer drill fitted with a chisel attachment. The debris was cleared and new pointing applied. For this I like to use a product called VDW800, we don’t sell it at Tile Doctor but its easily sourced on-line. and for my money it’s the best pointing product on the market. It can be used inside or outside, it’s totally waterproof but it’s also breathable, flexible and comes in four different colours.

Unlike Lime pointing this product fully hardens after twenty four to forty eight hours (depending on temperature) and it doesn’t wash out. Once the pointing was completed, we left it to dry overnight.

Next, we gave the floor a general clean with Tile Doctor Remove and Go which was sprayed onto the stone floor and then after about ten minutes worked in with a Black scrubbing pad fitted to a rotary floor machine. This is good for softening up paint and old sealers so they can be rinsed off with water and extracted with a wet vacuum.

Deep Cleaning Black Slate Flagstones

The next day our attention turned to the Slate flagstones which had been stained by all types of material that had accumulated over the years; this included paint, old sealer, and bits of Varnish to name a few, you name it this floor had it.

To renovate stone when it’s this bad they only option is to use a technique we call Milling that uses very abrasive “Milling Pads” encrusted with industrial diamonds to grind off the surface to reveal new stone underneath. It also makes the stone much more smoother to walk on and as a result easier to clean going forwards. A further benefit is a smoother stone requires less sealer. The milled floor combined with the new pointing should result is an almost new floor.

The great thing about offering this service is that the customer retains the look and feel of the original floor which in this case ran from the front room, passage, and Kitchen area.

The milling pads are applied using a floor buffer which is weighted to ensure a strong contact with the stone. It does generate a lot of dust though so we use water to contain the dust and help with lubrication. Once done the floor is rinsed with more water and the resultant slurry extracted with a wet vacuum.

The next step is to apply a sealer however the Slate needed to be completely dry before we could do that so it was left to dry out for a few days.

Sealing a Slate Tiled Kitchen Floor

Once the Stone had dried sufficiently (they never dry fully in old buildings without a DPM) the weather had changed for the worse and we had a full blizzard has arrived with snow and ice etc. It wasn’t ideal for sealing but the sealer we had chosen to use on this occasion copes well with damp due to it having an oil base and is rated for external use.

The sealer used is called Tile Doctor X-Tra Seal and is excellent on Black Stone as all Black Stones get their colour from the oil content inside the stone. The sealer fills up the pores in the stone resulting in a lovely dark sheen. The only disadvantage is its quite an expensive product however only one coat was needed and, on this occasion, it was the only sealer I would have recommended for this floor.

Once complete the floor looked completely transformed and should look great from many years to come. Assuming they and future owners of the property look after the floor it should never need Milling again just a deep clean and fresh seal ever five to seven years.

|  |

On the subject of maintenance, we took time to discuss after care cleaning before leaving and informed them to stay clear of using a steamer as this will damage the sealer. To clean this floor I recommended they use Tile Doctor Neutral Clean which is a mild but effective specialist tile cleaner that’s Ph neutral and comes in a concentrate so a little goes a long way. Naturally there are many tile cleaning products available in the market but you do need to careful as many are bleach bases and can harm the sealer, even washing up liquid which is a very good degreaser will damage a stone sealer.

Source: Tile and Grout Problem Solving Service and Products in North-Cumbria